CASE STUDY: Doing Quality Testing on Petzl Sitta with Customized Jig

Petzl Manufacturing Malaysia uses their jigs and fixtures measure of quality assurance for their product – Petzl Sitta.

While making jig and fixture is nothing new, what’s interesting is the way Petzl Manufacturing Malaysia integrate 3D printing into their existing processes.

If you own a manufacturing floor you would be very familiar with the usefulness of jig and fixture. They serve as a guide to provide repeatability and consistency.

Be it increasing productivity, or guiding assembly for the product, at the end of the day, jig and fixture helps in ensuring the quality of your product through a standardized dimension and process.

So what does that have to do with 3D printing?

Actually it does.

In this post, we will be sharing on why Petzl Manufacturing Malaysia decided to go ahead with 3D printing jig & fixture and a demonstration on how it works.

#1 Increasing Cost of Jig and Fixture

You won’t have economies of scale while doing jig and fixture.

Jig and fixture was tailored made for specific job across the assembly line. If you have 3 assembly lines with 3 different functions, that means you may potentially need 9 jigs and fixtures.

Assembly line example, imagine CNC that many jig and fixtures.

Do note that manufacturing industry in Malaysia is typically a high-mix industries, which involves a series of different projects with fundamentally different items – this means you need to develop even more jigs and fixtures.

Moreover, considering that the cost of jigs and fixtures made in aluminium – it does not come cheap. With the ever-growing amount of jig & fixture, you would hit a point where you spend more time managing inventory instead of manufacturing them, and this leads to the next point.

#2 Productivity Long Lead Time on Jig & Fixture

To increase productivity whilst maintaining high level of consistency and tolerance is not an easy feat.

What most manufacturers do is to create guides and templates i.e. jig and fixture to maintain quality.

However, spending extra machine capacity on making jig and fixture is tying up machine tools for production works – which is not money making activity.

On the other hand, outsourcing to other may have issues with lead time that take weeks.

Regardless of your choice, the ultimate issue here is spending time in getting the jig & fixture design right.

The design tolerance and function may not be optimal for the product – simply because machining tools in Malaysia are labor intensive.

With 3D printing, Petzl Manufacturing would just print them out at ease.

Watch How Petzl Uses It For Quality Assurance

This video was recorded during poka-yoke check. Poka-yoke is mistake proofing process that helps Petzl Manufacturing Malaysia to avoid (yokeru) mistakes (poka). This fool proofing process is meant to eliminate product defects by reducing human errors as they occur.

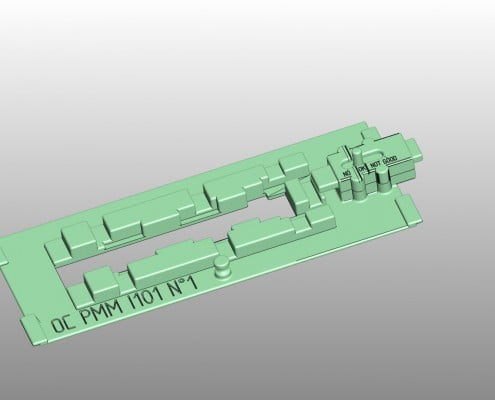

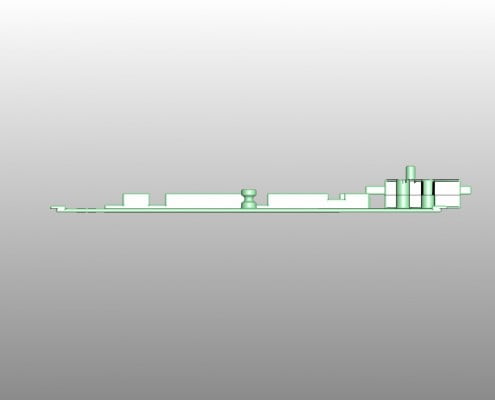

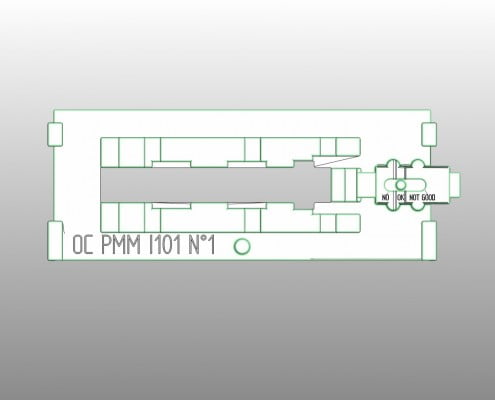

Here is a closer look on the digital file:

As a harness for mountain climbers, the gold ring needs to be sturdy enough to not buckle when it meets with a light tap. Conforming to it’s light weight design, the gold ring must be within a specified weight to ensure it doesn’t restrict the movement of mountain climbers.

This is why Petzl Manufacturing Malaysia came up with the 3 labels on the right of the jig – “no”, “OK” and “no good” as a testing measurement. As demonstrated in the video, the buckle on jig must not pass through the gold ring on Petzl Sitta to ensure it falls at the OK range.

Integrating 3D Printing as Part of The Core Process

The whole production of the jig only costs 2 hours and 23 minutes to print, with the cost of less than RM 140. This jig in particular was printed in ABS-M30, a thermoplastic material, this application however, is applicable in both technologies, be it FDM or Polyjet.

This not only gives more flexibility and empowering the design team to develop a functional jig, it would also be time saving as well for the company. Issues such as design validation or design iteration can be done without dwindling down on productivity as the whole process is automated.

Simply put, you can allow the machine to run overnight to produce the jig while everyone is resting while not compromising on productivity.

To learn more about industrial application for 3D printing – check out our industrial guide which is tailored made for specific industries.